Slipping Clutch Plate And Pressure Plate Replacement lower Cost 90044

Detail

New material research and development equipment

① laser particle size analyzer

In terms of material research and development, a laser particle size analyzer has been added to better start with material fineness and explore the relationship between fineness and products.

② friction material testing machine

In view of the existence of materials in the product, a friction material inspection machine was purchased to detect whether there is agglomeration, blistering, etc.

③ Resin polymerization equipment, tap density meter

With the increase of batches and quantities of materials, the testing and research and development of related materials are also increasing. This year, testing equipment has been added for some testing items.

Specification

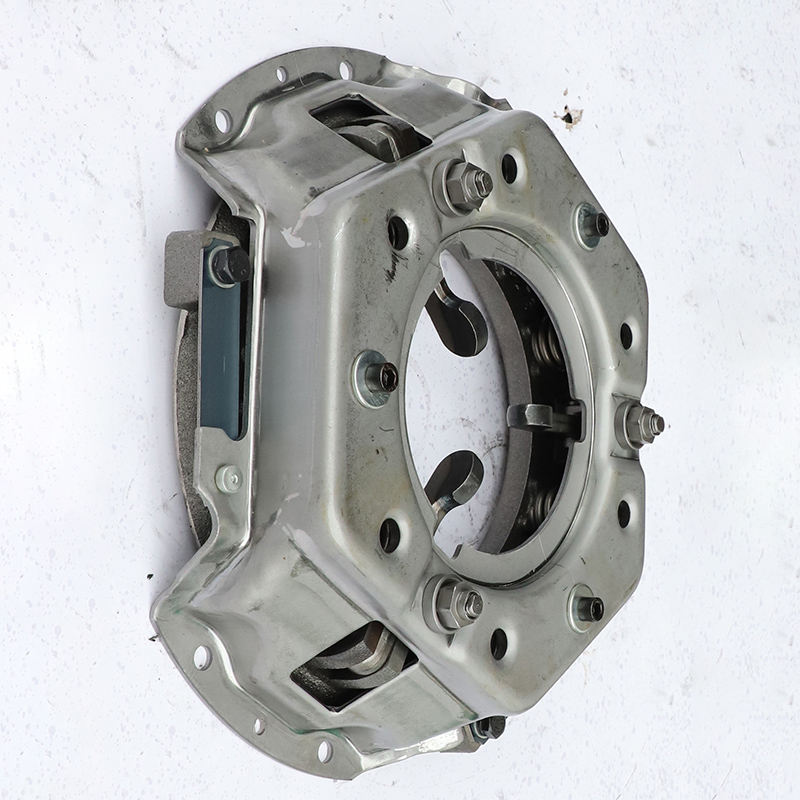

Drawing No.: 90044

Name: TCM Forklift

Specifications: 275X170

Number of mounting holes: 6XΦ9

Positioning hole: 3XΦ6

Applicable models: 3 ton forklift

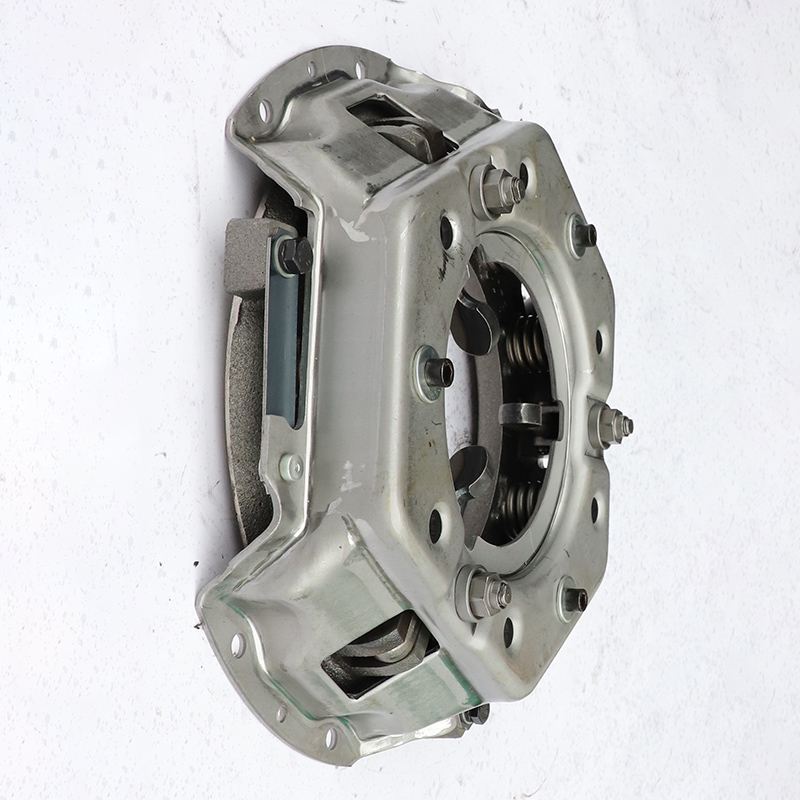

Clutch Pressure Plate

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

|

No. |

Specification |

|

80010 |

430x260-10x52.3 |

|

80042 |

430X240-24X50 |

|

80047 |

308X191-10X38.4 |

|

80076 |

255X160-24X25.6 |

|

No. |

Specification |

mounting holes |

positioning hole |

|

80010 |

430X240 |

12XΦ11 |

--- |

|

80042 |

420X220 |

12XΦ11 |

--- |

|

80047 |

275X170 |

6XΦ9 |

3XΦ6 |

|

80076 |

300X190 |

10XΦ10.7 |

2XΦ10 |

Model Table

|

Category |

No. |

Applicable models |

|

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

--- |

|

5300 |

--- | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate

OE standard, CCC certified

Classification

Clutch Pressure Plate

Imported steel, quenched spring fingers, strong and wear-resistant Significantly improved.

High-strength metal plate to ensure heat dissipation, avoid high temperature deformation, improve Comfort and stability.

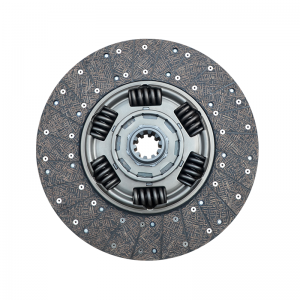

Wear-Resistant Type

Clutch driven disc assembly (wear-resistant type) The skeleton material is composed of high-quality glass fiber, acrylic fiber and high-component red copper wire, high-temperature resin and rubber are used as binders, and high-quality imported friction performance regulators and high-quality fillers are used. And so on, with advanced technology for production. It has excellent joint smoothness and wear resistance, stable friction coefficient, and is suitable for various models.

Comfortable Type

Clutch driven disc assembly (comfortable type) adopts high-quality chemical fiber and high-quality glass fiber twisted material as skeleton material, high temperature resistant resin and rubber as adhesive, with high-quality friction performance modifier and filler, and is produced by traditional technology. become. It has the characteristics of high temperature resistance, wear resistance, high rotational burst strength and stable friction coefficient. Suitable for light, medium and heavy trucks. Excellent quality assurance The friction material is made of superior materials to make the friction coefficient more stable. Excellent braking performance The unique friction material formula shortens the braking distance and effectively guarantees driving safety. Comfortable driving experience Comfortable pedal feel, quiet braking operation, let the brakes do what you want.