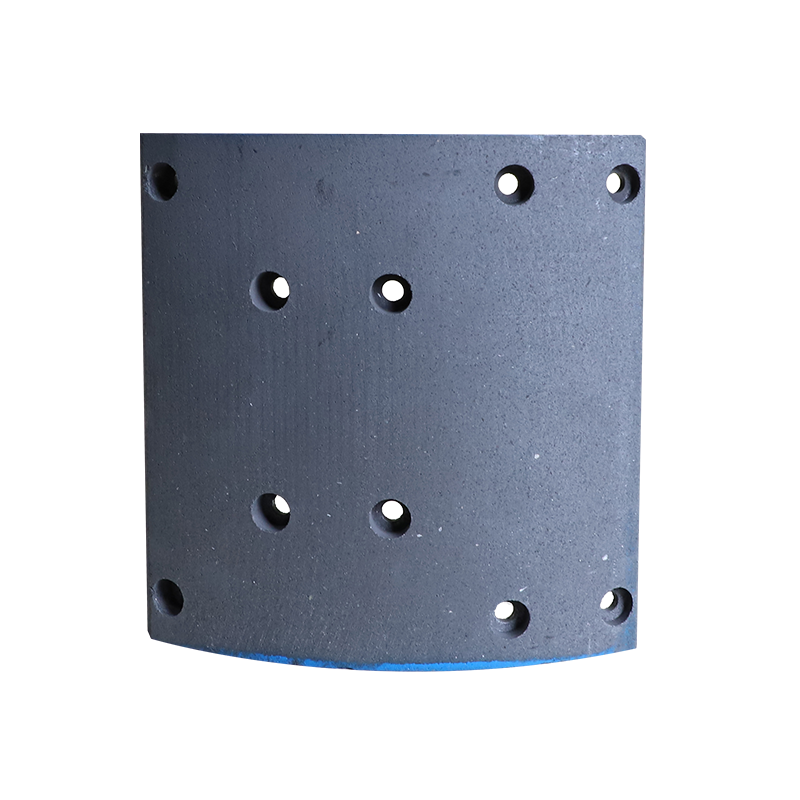

ODM High Quality Semi-Metal Brake Pads Factories – BPW Friction Material Rear Trailer Truck 29228 Brake Lining With Good Price – Feiying

ODM High Quality Semi-Metal Brake Pads Factories – BPW Friction Material Rear Trailer Truck 29228 Brake Lining With Good Price – Feiying Detail:

Detail

Brake pad life

What’s the matter with the short life of the brake pads? Why do inferior products have long braking distances in emergency braking situations?

Answer: Like all objects, the strength of intermolecular links in the material organization decreases at high temperatures. The principle of braking is to convert kinetic energy into heat energy in the form of friction to achieve braking (energy balance theory). Therefore, a large amount of heat generated by the friction between the brake pad and the disc will accumulate on the surface of the friction material of the brake pad. In order to maintain sufficient strength of the brake pads under such high temperature conditions, materials such as high-temperature resin, high-purity graphite, and high-purity barium sulfate must be selected.

For inferior brake pads, they will not use such high-end materials, so they cannot guarantee stability at high temperatures, and as the speed increases, the heat will be more, the temperature will be higher, and the link strength will be lower, thereby reducing the brake pads. Dynamic ability, manifested as extended braking distance. Therefore, the brake pads that you feel comfortable driving at a speed of 20 to 60 kilometers per hour in the city do not mean that you have the same stable braking distance performance at high speeds. When the link strength of the molecular chain is reduced at high temperature, its wear and tear is accelerated, which is why the service life of general brand brake pads is very short in mountainous areas or in the state of frequent sudden braking.

Specification

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

|

No. |

Specification |

PS. |

|

80010 |

217.5*107.5*31 |

Castings, spring bars and snaps are installed |

|

80042 |

247*109.5*30 |

9.0 thick, steel mesh steel back, with 4 spring bars |

|

80047 |

210.6*114*29.7 |

casting |

|

80076 |

220*91*30 |

Steel mesh steel back including 4 spring bars |

Model Table

|

Category |

No. |

Applicable models |

|

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

— |

|

5300 |

— | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate; OE standard, CCC certified

Classification

Gifts Series

1. Environmentally friendly, non-asbestos and low metal formula

2. High friction coefficient, providing high braking force during use

3. Smooth braking

4. High cost performanceon various roads

High-end series

1. Environmentally friendly, non-asbestos and low metal formula

2. The friction coefficient is high and stable to ensure the safety of braking

3. Low wear rate and long service life

4. The friction surface is brushed with imported zebra-pattern glue, and the brake disc is cleaned during use to provide high initial grinding braking force

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for ODM High Quality Semi-Metal Brake Pads Factories – BPW Friction Material Rear Trailer Truck 29228 Brake Lining With Good Price – Feiying , The product will supply to all over the world, such as: Lithuania, Durban, Rome, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

![Famous Best Truck Service Brake Pads Products – [Copy] Factory Hot Sale 5200 Brake Lining Manufacturing Brake Shoes Lining For Truck Part DT5300 – Feiying](http://cdn.globalso.com/toughprobrake/5200-5300-1.png)